Advantages and welding methods of stainless steel welded pipe fittings

Release time:

2020-12-12 12:05

Source:

www.chinasanqing.cn

Author:

Sanqing

Number of views:

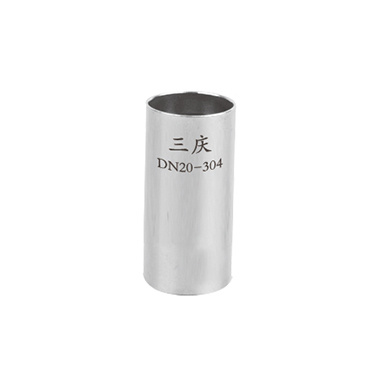

stainless steel welded pipe fittings are the main indicators of the "Green Building Evaluation Standard" vigorously promoted by the state in recent years: the main component of healthy drinking water. First-tier cities such as Beijing, Shanghai, Guangzhou and Shenzhen and many provincial capitals have successively issued corresponding water supply construction standards and water supply renovation standards for old districts.

Among them, stainless steel welded pipe fittings are listed as pipes for new and rebuilt water supply systems. The advantages of stainless steel piping system has been introduced in detail by many professionals, such as health and hygiene, avoiding secondary pollution of water quality; corrosion resistance, service life can be the same as that of buildings; high strength, even resistance to natural disasters such as earthquakes, no leakage; environmental protection and non-toxic, Unlike rubber and plastic pipe fittings that need to be fused and bonded when connected, toxic chemicals will be produced. Stainless steel welded pipe fittings do have a lot of advantages compared to other pipes.

In addition to the water supply network built at the government level, more and more families now choose stainless steel piping systems as pipes for domestic water supply systems. When it comes to piping systems, it is natural to connect pipes. The quality of the pipe connection directly determines the durability and safety of the pipe. Today, the author will talk about the connection of stainless steel pipes.

Historically, the connection methods of stainless steel welded pipe fittings mainly include welding and crimping. Among them, the origin of welded pipes is the earliest, but due to its complicated operation and high requirements for operators, some pollutants will inevitably be produced during the welding process, and it is generally not necessary to connect domestic water pipes. The crimping type is widely used for the connection of various pipes. For example, our common fire water pipes are large-diameter pipes, which are connected by groove type (also called clamp type), while small and medium-diameter stainless steel pipes are mostly connected by crimping type. The crimping connection is also the connection method used by most of the domestic water stainless steel pipes in our daily life. We will focus on this link below.

Crimp connection refers to the pipe connection method that uses the effective rigidity of the material itself to crimp with a clamp (or mold or jaw). Stainless steel pipe crimping connection is mainly divided into three forms: 1. Double card crimping type; 2. Single clip type; 3. Ring pressing type. These three connections have their own characteristics.

Latest News

2023-02-12