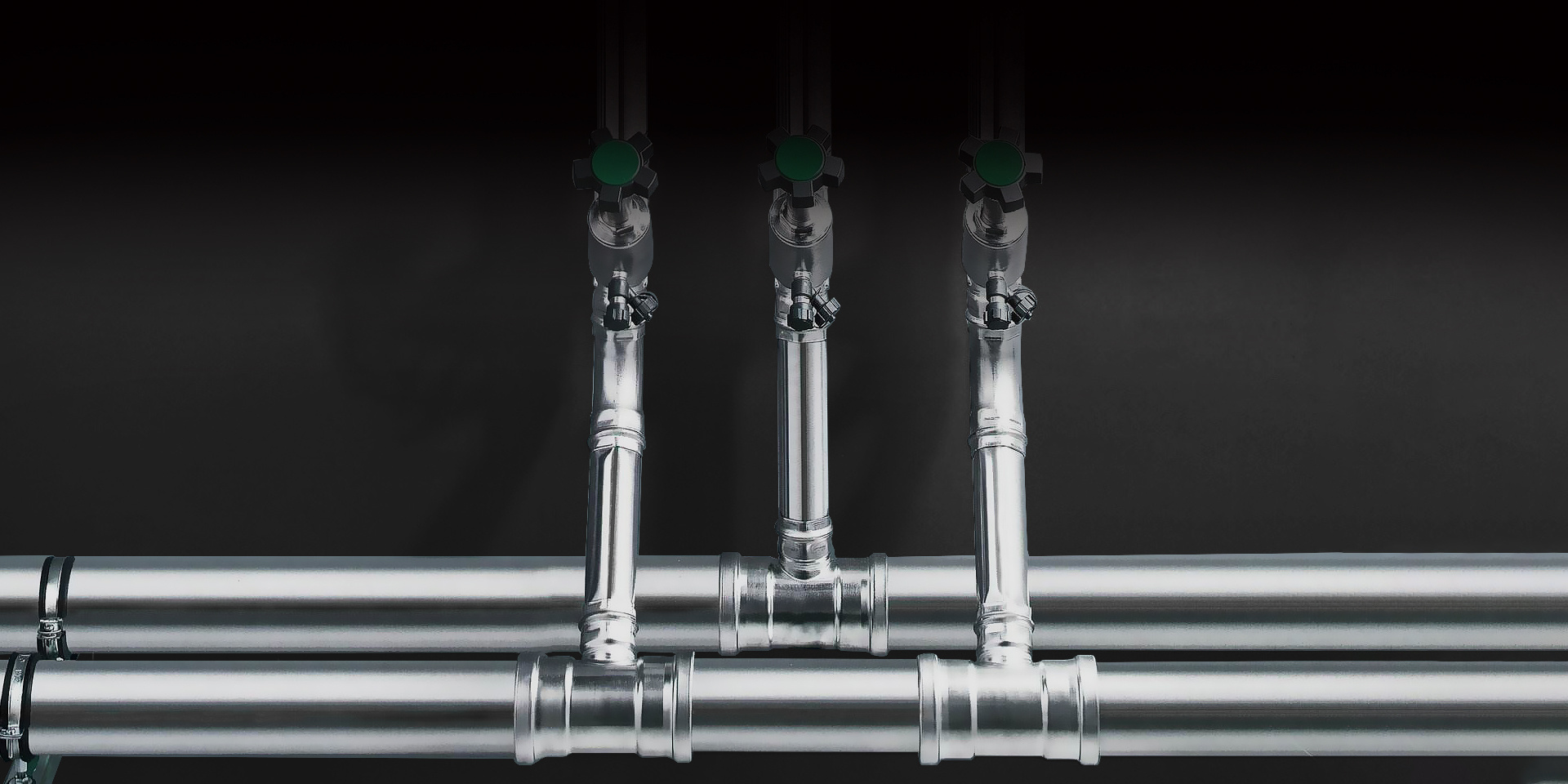

Sanqing Pipe Industry: Problems and Solutions of Pin-pressing Pipe Fittings

Release time:

2020-10-19 10:58

Source:

Author:

Number of views:

Sanqing Pipe Industry will have various problems in the whole process of clamping. Now, a basic summary has been made on the problems that often occur in the whole process of clamping.

Sanqing recommends the problems and solutions of clamping pipe fittings:

1. The hydraulic cylinder never returns, and the shaft rod is stuck in the pipe fitting part and does not return with the hydraulic cylinder. The first reason for the clamping type stainless steel water pipe

is that the anaerobic glue is not cleaned clean and tidy, and the solution for sticking the shaft rod

is to clean and tidy the anaerobic glue of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the shaft rod of the clamping rod of the clamping rod of the clamping rod of the clamping rod of the clamping rod of the clamping rod of the clamping rod.

Reason 2: There is debris in the pump body, which blocks the oil return.

Solution: High-pressure clean the pump body and remove the oil.

Reason 3: The hydraulic cylinder skeleton seal gap is not large

Solution: Remove the hydraulic cylinder or skeleton seal.

2. Stainless steel plate clamping type pipe fittings The pipe fittings are not clamped immediately. Plastic-coated stainless steel water pipe

Reason 1: Loose oil pipeline socket and oil leakage.

Solution: Tighten the oil pipeline socket.

Reason 2: The shaft is destroyed.

Solution: Remove the new shaft. (Electrical adhesive tape can be temporarily wound on the pipe fitting clamping part for 2-3 weeks or 0.2mm copper sheet, and then clamping can be supplemented)

Reason 3: The oil pump cannot apply pressure (curing).

Solution: Remove the hand pump and remove the oil.

2. Loose pipe fittings and pipes occur after stainless steel plate clamping pipe fittings are pressed.

Reason 1: The interval between the fixed brackets is too large, and the shaking amplitude of the clamped pipe fittings during the whole installation process is large

Solution: Improve the fixed brackets according to the installation specifications, and then use the clamping pliers to supplement the loose socket connection.

Reason 2: The 0-ring falls off (when the pipe is inserted into the pipe fitting, the 0-ring is pushed away from the U-shaped groove)

Solution: Remove the pipe fitting with loose socket connection with a pipe cutter or angle grinder, and clamp again with a new pipe fitting.

Reason 3: The pipe is obliquely inserted into the pipe fitting. When clamping, the angle between the pipe and the pipe fitting is too large.

Solution: Use a pipe cutter or angle grinder to remove the loose pipe fittings, and use new pipe fittings to clamp again.

reason four: shaft damage is too large.

Solution: Disassemble the new shaft rod and clamp the pipe fitting again.

and above are the contents collected by Cangzhou Sanqing Industry and Trade Co., Ltd. for everyone. If necessary, please contact us.

Latest News

2023-02-12